Taking things off and letting it all hang out.

Taking things off and letting it all hang out.

*** WARNING ***

The information present within these pages are for educational

purposes only. If you choose to follow these procedures and end

up damaging your BMW R1200GS, it is not my fault as it is your choice

that you follow the text describe here. Your actions are yours to

make and I, in no way shape or form, am responsible for your desire to

follow the pictures and text describe here in. The information is

presented as is and is not guaranteed or warrantied in any way.

Do this at your own risk.

*** WARNING ***

*** Note ***

It

is absolutely essential that a torque wrench be present for this

procedure. Trying to tighten anything on a R12GS without a

torque wrench is just asking for trouble. Go visit Sears if you

don't have a torque wrench. They'll be more than happy to lend

you one indefinitely for a moderate sum of money.

*** Note ***

To start with, I put the bike on the center stand.

I made sure I have a good clean area and there is a lot

of space to lay out parts as I take them off my bike. It

doesn't hurt to be anal and lay things out in a manner that I can

easily reverse the disassembly process later. If I had a bike

jack, that would be awesome. However, all I have is the concrete

garage floor. It does the job. It doesn't do my

back any good though.

The tools I'll be using for this

exercise:

- T40 torx wrench

- T30 torx wrench

- 3mm hex wrench

- crescent wrench

- torque wrench

- .15mm feeler gauge (intake)

- .30mm feeler gauge (exhaust)

- 16mm spark plug socket

- BMW primary/direct ignition coil puller ($16+ for piece of

plastic that you can't live without)

Helpful things I have but are not absolutely necessary:

- Vaseline (petroleum jelly)

- BMW TDC finder tool ($50+ dollars for a bent metal rod)

- Thread lock (blue - temporary)

Before attempting to do anything related with the valves I make sure the bike is

absolutely cold. I have let the bike cool down over

night to perform this valve work.

Since I have the Touratech engine guard and the Touratech head guard

(over kill), I have to remove those items before starting

anything.

2. Main engine guard bolt. Right

side and left side. Screws 3 and 4.

3. Top screw. Right side and left side. Screws 5 and 6.

Even though I have listed the screws in this order, I don't necessarily

unscrew things in this manner. I just make sure the engine guard

is secure enough that it

doesn't crash to the ground as I remove it.

Engine guard removed.

It didn't take long to remove the engine guard. About 10

minutes. Not bad. Next I have to remove the head

guard. I won't be putting the head guards back on as it is really

not needed when the engine guard is in place. I wanted to make

sure the 12GS is well protected but eventually felt that the head guard

us just sitting there when the engine guard is in place.

Not only that, it's adds weight.

Three screws later (per each head) and the head guard is off.

Head guard.

Engine guard and head guard. Notice my super spiffy home grown

highway pegs are still on the engine guard.

Now it's time for the real operation. First thing's first.

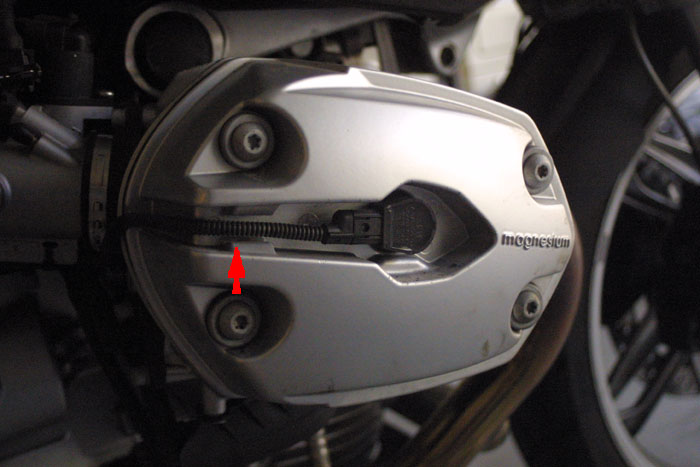

I have to get the ignition coil cable cover off. I haven't done

this in a

while so I had to relearn where the key spot is to remove the

cover. Actually,

all I have to do is insert a flat head screw driver (the one that is

supplied in the wimpy tool bag that comes with the R12GS will do fine)

at the area right before the spot where the cover makes a 90 degree

bend.

I insert the screw driver and apply a little leverage. The cover

pops right off.

Approximately where the red arrows point.

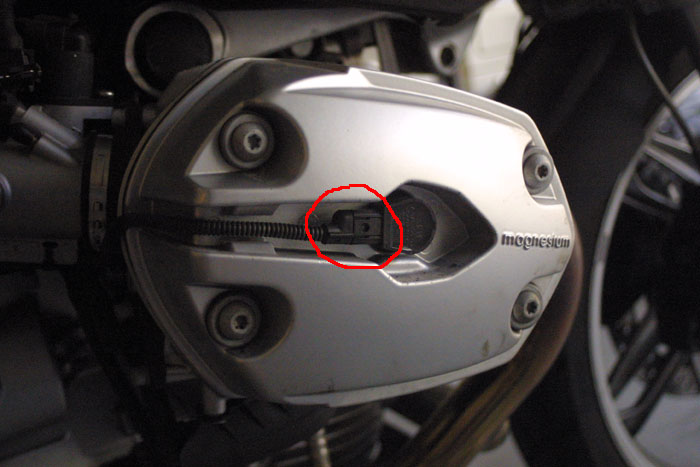

I do the same for the other head. Now I have to disconnect the

ignition cable. This can be done using a small screw driver to

ever so lightly lift the latch on the primary/direct ignition

coil. I'm very gentle here. I don't want to over torque

anything and

cause the latch on the primary/direct ignition coil to break. If

it does break, that means I'll have head to my nearest BMW

dealer for a replacement primary/direct ignition coil. That would

suck. I don't know how much the part cost as I have never

purchased a replacement, but it's can't possibly be cheap.

I do the same for the left head. Again, I'm very careful and take

my time.

Yes, my left head cover is scratched. I dropped my 12GS on the

second day I got it. Bummer but life goes on.

It should look something like the picture below.

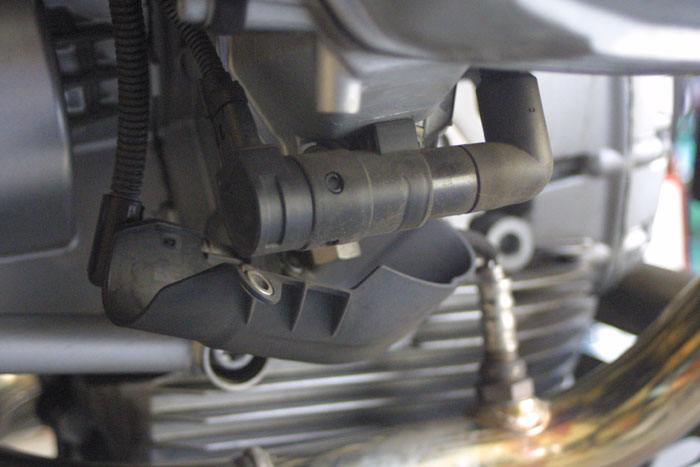

Next, I will remove the cover for the secondary ignition coil

using the T30 torx wrench. Two screws total on each side.

I'm careful here as

well because the oxygen sensor wires are also attached to the cover for

the

secondary ignition coil. I make sure to be graceful and not use

any excessive force.

I move the cover out of the way but I make sure not to effect the

oxygen sensor

wiring.

At this point I'm ready to disconnect the ignition cable for the

secondary ignition coil. The wire's connector is the same as the

primary/direct ignition coil. Again I use a small screw

driver to ease the latch up so I can pull the connect off. Once

again I'm careful

not to damage the latch on the secondary ignition coil. The

ending result is something like this:

The cool thing about the ignition coil

connectors, they're keyed. I can't possibly mess up when I

reattach everything.

While I'm down there, fidgeting with the secondary ignition coil, I

went ahead and disconnected the secondary ignition coil from the spark

plug. This can

be done without any tools. A slight tug on the secondary ignition

coil will have them come right off. I hear that wonderful

popping sound when the ignition coil comes off.

The primary/direct ignition coil is not so easy. I need a

special tool from BMW to remove these babes. I purchased the

puller from Brown BMW dealer in Pomona a while back when I did my valve

check for the 600 mile break in. The version I have is a small

plastic tool. I've seen other versions of the tool but this

is the one the dealer sold me. It works well enough I guess.

On to the primary/direct ignition coil it goes. This one has a

tendency to slip as the primary/direct ignition coil is extremely well

connected. I swear there is a vacuum to contend with when it come

to

removing the coil. BTW, swearing is allowed when I try to pull

the primary/direct ignition coil. It was a pain to

pull off. Eventually it comes off after several slips of the

tool.

Here is what the tool looks like when it's seated on the primary/direct

ignition coil.

It's oh so sweet when I hear that final popping sound as the

primary/direct ignition coil comes out. Now I have a direct line

of sight to the primary spark plug and the secondary spark plug.

If you look hard enough, you'll see the spark plug sitting inside.

Secondary spark plug.

Now comes the 16mm socket to remove the spark plugs. I attach the

socket to a wobble ratchet extender and remove the primary spark plugs

from both heads. When it comes to the secondary

spark plugs, I had to use some Vaseline on the outside of the socket in

order for the 16mm socket to slide inside the hole and unscrew the

spark

plugs. I'm gentle on the plugs as I don't want to damage the

porcelain on the plugs. A little bit of effort and the

plugs are all out. I inspect the plugs to see if there is

anything strange about how the engine has been firing. The plugs

are white with a little brown to them. An indication that the

bike is still running lean. That's fine I guess as I really don't

have

any control as to how rich the bike should be running. I didn't

install one of those fancy gadgets to allow for high altitude running.

I'm not putting in new plugs this time but will for sure the next valve

adjustment round.

The next thing I do is to cover all of the ignition cables with plastic

and electrical tape to keep them clean and to prevent any oil from

coming in contact with the cable. This step is probably not

necessary but it doesn't hurt to spend an extra couple of minutes to

make sure things are protected.

Now I'm ready to remove the head

covers. I use the T40 torx wrench to loosen the head covers.

I made

sure I have something to catch oil coming out of the head

covers. I estimate the amount of oil loss is in the neighborhood

of 1/2 a quart for both heads total.

When I unscrew the head cover bolts, I only unscrew

the bolts until I can pull them away from the head cover. There

is no need to remove the bolts themselves.

Unscrew just enough to...

Pull them out.

Next I give a little heave and a little ho and the head cover come

right

off. Yes, oil goes all over the place.

Here's an example. A pool of oil. This is just the left

head.

Now I can see it all hang out. Pretty cool if you ask me.

Main page

Page 2 - Tweaking the valves.

Written on: February 18, 2007

Last modified: February 19, 2007